Macerator toilets, a common solution for homes without conventional plumbing systems, offer unique advantages but also come with their own set of potential challenges.

These innovative units, unlike traditional toilets, rely on a specific process to move waste, which while effective, can sometimes lead to distinct issues. With knowledge and a little maintenance, most common problems can be easily recognized and perhaps even prevented.

Whether you’re a homeowner living with a macerator toilet or someone considering the installation of one, understanding how these devices operate, along with their common issues and fixes, can be a valuable insight.

Understanding Macerator Toilets

Understanding Macerator Toilets

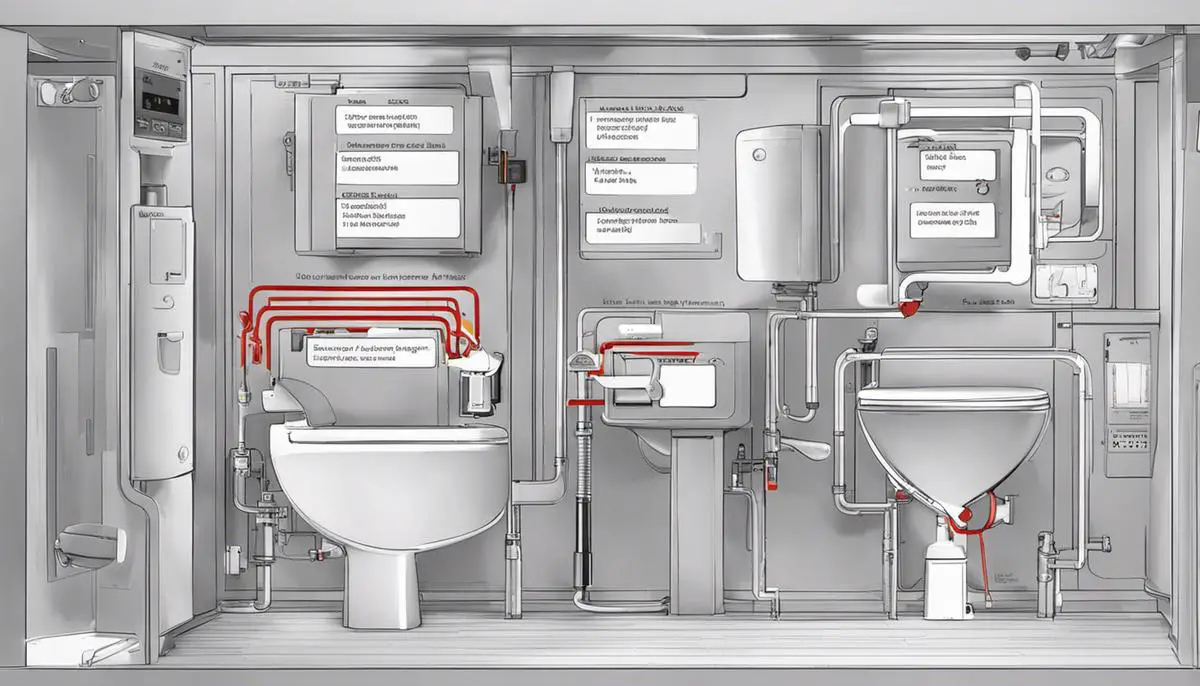

Macerator toilets are a type of plumbing fixture that breaks down human waste into a slurry, or paste, which can then be pumped into the existing sewage system.

Traditional toilets rely on gravity to remove waste, however, macerator toilets are constructed with a grinding mechanism. This innovative design allows for flexibility in installation locations, including below or distant from sewer lines, which is a major benefit for homeowners with unconventional or challenging floor plans.

Macerator toilets function using a high-powered blade located in a chamber behind the bowl, which shreds human waste and toilet paper into small particles.

Once the waste is ground into a slurry, it is then pumped away through a small-diameter pipe connected to the existing wastewater system. The system runs on electricity, and operates automatically when the toilet flushes.

This type of toilet differs from standard toilets in several notable ways beyond just the mechanical workings. Since macerator toilets can be installed virtually anywhere, they’re an ideal solution for basement bathrooms, home additions, or other areas where traditional plumbing may not be feasible.

Moreover, because they use a small-diameter discharge pipe instead of large sewer pipes, they require less extensive excavation and soil disturbance during installation.

Deciphering Potential Obstacles with Macerator Toilets

Though macerator toilets provide a variety of benefits, they are not immune to complications.

Their expensive cost, encompassing not only the initial purchase but ongoing maintenance and potential repairs, is a common concern.

The mechanisms, including the blades and pump, may occasionally need attention, while the electric motor also presents a possible point of failure.

Blockages are frequent problems with these toilets, often caused by foreign objects like wet wipes, sanitary products, toys or even deodorant caps – all of which have the potential to jam the grinding mechanism.

The operational noise level of the macerator toilets is higher due to the grinding and pumping processes, and could be problematic for some users.

A significant downfall of a macerator toilet is the requisite for electricity. If there’s a power outage, be aware that these toilets cease to function.

Some models have an emergency backup reservoir, but these are often limited in capacity and provide no solution for the problem of waste disposal during prolonged power outages.

Even though the small-diameter discharge pipe allows for ease in installation, it also presents a higher risk of getting blocked compared to traditional sewer pipes.

Possible causes for these blockages include an accumulation of insufficiently ground solids or the collective impact of soaps, fats, and grease from non-toilet wastewater sources.

Incorrect installations of macerator toilets can lead to foul odors due to improper ventilation or poorly sealed grinding chambers. And, of course, the specifics of installation are important factors influencing the warranty, adding another level of consideration for homeowners.

Common Problems with Macerator Toilets

Enhancing Knowledge on Macerator Toilets

A macerator toilet, or an upflush toilet, is a practical solution where the installation of a conventional gravity-fed toilet is impractical, such as basements and home extensions.

This type of toilet uses a specialized maceration and pumping system for waste elimination. While they offer several advantages, it is also important to acknowledge that they are susceptible to a range of problems.

Blockages in Macerator Toilets

Like any other toilets, a macerator toilet can also become blocked. This often happens when inappropriate items, such as baby wipes, feminine hygiene products, or excessive amount of toilet paper, are flushed down the toilet.

These items can clog the cutting blades of the macerator, resulting in inefficient operation. Signs of a blockage may include the toilet not flushing properly or the macerator continually running.

Failure to Flush

At times, a macerator toilet might fail to flush completely or effectively. This could be due to a number of reasons such as mechanical issues, electrical failures, or blocked pipes. Mechanical issues could be anything from breaking down of the macerator’s motor to problems with the float switch.

Power failures could result in the pump being unable to dispose of waste. Blockages could prevent water and waste from being pumped out of the system.

Strange Noises

Macerator toilets might sometimes produce unusual noises which could be an indication of underlying problems. High-pitched or grinding sounds could signal an issue with the macerator blades.

Bubbling or gurgling noises might suggest air trapped in the system or blockages. Persistent humming could indicate a stuck or faulty motor.

Leaks in Macerator Toilets

Leaks are another recurring issue with macerator toilets. Leaks can occur if the toilet isn’t installed correctly, or because of wear and tear over time.

The rubber seals that hold the toilet together can become worn out and fail to keep water contained. A leaking macerator toilet can cause water damage and should be immediately addressed.

Problems with Macerator Pump

Sometimes, the pump in a macerator toilet might cease to function efficiently.

This could be due to a number of reasons, such as a tripped circuit breaker, a faulty pressure switch, or worn out capacitors.

An underperforming, or a failing pump will struggle to push water uphill, leading to inefficient flushing and possible blockages.

Optimizing the Functionality of Macerator Toilets

Preventive measures, regular maintenance, and strict adherence to manufacturer’s guidelines contribute significantly to the optimization of macerator toilets.

Ensuring the system is properly cleaned and de-scaled will facilitate an efficient operation and enhance the longevity.

Respecting what substances can and cannot be flushed will maintain the integrity of the toilet.

Using the appropriate replacement parts when necessary is key to ensuring consistent functionality and reducing the occurrence of issues associated with these systems.

Finding the Cause

Recognizing Issues in Macerator Toilets

Macerator toilets, known for their dependability and efficiency in breaking down waste and toilet paper to be pumped into your home’s main plumbing system, can still experience occasional problems.

Rapid detection and understanding of any malfunctions are key in managing these issues effectively.

The subsequent section offers a detailed guide to spotting potential problems and provides several troubleshooting tips to help you navigate any difficulties you may encounter.

Common Issues and Troubleshooting Steps

Macerator toilets can suffer from a variety of issues. Some of the most common ones include noises, leaks, non-starting macerator pumps, blockages, and bad smells.

Here is a step-by-step guide to diagnosing and addressing these common problems:

Noises

Macerator toilets are not known to be noise-free, but excessive noise can signal a problem. If your macerator toilet is making unusual noises, it may be due to a malfunctioning macerator pump or an obstruction in the system.

Disassemble the unit carefully following the manufacturer’s instructions and inspect for improper functioning or obstructions. If the pump is damaged, it may need to be replaced.

Leaks

Leaks can occur at any point in the macerator toilet system. They can be due to cracks in the unit, loose connections, or worn-out seals.

Inspect the unit and the connecting pipes thoroughly for any signs of leaks and tighten any loose connections. If parts are cracked or seals are worn out, you might need to replace them.

Non-Starting Macerator Pumps

Your toilet’s macerator pump may not start due to a malfunctioning motor or a blown fuse.

Check the fuse box to ensure the fuse pertaining to your toilet’s macerator hasn’t blown. If the fuse isn’t the problem, you likely have a more significant issue with the motor, and it might need replacing.

Blockage

A blockage can cause the macerator toilet not to flush properly or lead to a backup of sewage.

Disassemble the unit to look for blockages and carefully remove any obstructions found. Remember not to flush anything other than toilet paper and human waste down the toilet to prevent such occurrences.

Bad Smells

A foul smell emanating from a macerator toilet could indicate a blockage, a cracked seal, or issues with the venting.

Follow the same procedures as outlined for blocking and leaking. If the problem persists, consult a specialist plumber as the issue might be too complex for a DIY approach.

Macerator Toilet Maintenance

To avoid potential issues with your macerator toilet, it’s crucial to carry out regular maintenance and routine checks.

Always use it as per the manufacturer’s recommendations, and refrain from flushing non-suitable materials or substances. Implementing a regular cleaning routine will not only enhance the toilet’s efficiency but will also extend its service life.

While troubleshooting common problems can certainly be beneficial, keep in mind some complexities might necessitate professional input. If any discomfort arises in diagnosing or fixing problems, or if the issues continue to persist despite your efforts to solve them, never hesitate to enlist the support of a seasoned plumber.

Fixing the Problem

Potential Issues with Macerator Toilets

Macerator toilets differ significantly from standard flush toilets in their design. They incorporate a macerator pump that transforms solid waste into a liquid slurry, which is subsequently flushed down the sewage line.

This toilet design proves beneficial in places where the installation of traditional gravity flush toilets poses a challenge. However, these advanced toilets can also experience a unique set of problems.

Blockage Issues

One frequently encountered problem with macerator toilets is blockades. This commonly occurs when items that cannot be easily macerated, like sanitary napkins, wet wipes, or diapers, are flushed down the toilet.

As a result, the macerator pump can’t break down these materials, leading to significant blockage.

To resolve this issue, the offending items need to be manually removed from the unit – this task may require professional help. Users should also be educated about what can and cannot be flushed down a macerator toilet.

Overheating Problems

Another common issue with macerator toilets is overheating. This usually happens when the toilet is continually used within a brief period without giving the pump enough time to cool down. Overheating can destroy the motor and impair the overall toilet function.

The best solution to this problem is to allow a few minutes gap between multiple flushes. If the motor is already damaged, replacement by a professional may be necessary.

Sensor Issues

Some macerator toilets come with a sensor that detects when the wastewater tank is full, prompting the macerator to start its operation. A malfunctioning sensor may fail to initiate the macerator, leading to a failure in flushing the toilet.

Fixing sensor issues may need technical expertise. If the toilet is still under warranty, it is best to contact the manufacturer for repairs.

Macerator Pump Failure

The most significant issue faced by macerator toilets is the failure of the macerator pump itself. Whether because of wear and tear over time, or due to a particularly stubborn blockage, if the macerator pump ceases to function, the toilet won’t be able to flush.

In a scenario where the pump fails, the entire unit generally needs to be replaced, which requires professional help. Regular maintenance of the unit can help to prolong the lifespan of the pump and prevent pump failure.

Failure to Flush

This problem could be due to various reasons including blocked hoses, a blown fuse, or a flipped circuit breaker.

It may be solved by checking for hose blockages, replacing blown fuses, or resetting flipped circuit breakers. For persistent problems, a professional plumber should be consulted.

Maintenance of Macerator Toilets

To avoid the majority of issues that may arise, regular upkeep of a macerator toilet proves to be essential.

A good maintenance routine involves using suitable cleaning products, ensuring nothing other than dissolvable toilet paper is flushed down, replacing worn parts in a timely manner, and arranging for regular inspections by trained professionals.

Maintaining Your Macerator Toilet

Common Problems with Macerator Toilets

Despite their efficiency, macerator toilets are not immune to drawbacks. They function by using rotating blades to liquidize waste and toilet paper, which is then pumped to a drainage pipe.

This complex operation can invite several problems like blockages, leaks, and troubles with the motor and electrical parts.

Frequently encountered issues include obstructions caused by non-dissolvable items getting trapped in the mechanism, difficulty in flushing, ongoing water flow, and off putting odors.

Common Causes of Macerator Toilet Problems

The key to maintaining a macerator toilet is to understand the common problems it can face. Partitions or blockages are typically caused by excessive use of toilet paper or non-dissolvable items, including wipes and sanitary products, being flushed down the system.

These items can jam the chopper mechanism, impede the efficiency of the system, or cause it to stop working altogether.

Electrical problems or motor failure can also occur in macerator toilets. Prolonged use or wear and tear can lead to the failure of the motor or even damage the electrical circuitry. Additionally, leaks can occur due to flawed installation or aging pipes. The leakage can happen due to damage to the seals, cracks in the macerator casing, or pipe corrosion.

Effective Maintenance of Macerator Toilets

To properly maintain a macerator toilet and avoid potential problems, regular checks are necessary.

Look for signs of leaks, unusual noises, and odors that arise from the toilet. Regular cleaning is also essential.

Avoid using bleach or harsh chemicals as these may damage the seals or gaskets and degrade the maceration blades. A mild cleanser or vinegar is usually a safe and effective cleaning solution.

Conducting regular maintenance checks will also help identify any aging parts that might need replacement.

This ought to be done at least once every six months or as soon as an issue is identified.

The rubber parts, seals, and gaskets should be checked for wear and tear, while the chopper blades should be inspected to ensure they are not dull or damaged.

Extending the Lifespan of a Macerator Toilet

Use the macerator toilet correctly, following manufacturer guidelines and instructions. Regular maintenance, avoiding harsh chemicals, and flushing only recommended waste (dissolvable toilet paper and bodily waste) can substantially extend the lifespan of a macerator toilet.

Do not attempt to fix any complex issues yourself as this could cause more harm than good. In cases where the problem seems unsolvable or the toilet is frequently breaking down, it might be best to contact a plumbing professional or the manufacturer.

Finally, keep spare parts available for quick replacements when needed. As maceration toilets have mechanical parts, these will inevitably wear out after some time. Having readily available spare parts will reduce any down time experienced due to a broken part.

While macerator toilets may present unique challenges, getting accustomed to them and their benefit towards decentralizing sewage systems can be key in finding them an asset rather than a liability.

Regular maintenance and precautionary measures can significantly minimize the occurrence of problems and extend the lifespan of your unit.

Understanding the signs of common problems, how to identify causes, and skills for fixing the issues can give you peace of mind and keep your macerator toilet running smoothly.

Through the knowledge shared, may you find the competence and confidence in handling this modern solution to our plumbing needs.

[faq-schema id=”16622″]

![How to Remove Crystallized Urine [Explained]](https://homepander.com/wp-content/uploads/2022/02/How-To-Remove-Crystallized-Urine.jpg)

![How To Clean Dark Grout That Has Turned White [5 Easy Ways]](https://homepander.com/wp-content/uploads/2021/12/How-To-Clean-Dark-Grout-That-Has-Turned-White.webp)